History of Investment Casting

Investment casting is the refined, refurbished, and modern high-end variety of the age-old form of casting. This form of casting is used for various purposes, including the construction of aircraft engines for both civilian and military purpose. Based on the lost form of casting, investment casting in India is considered to be the primary casting technique in modern times.

It had incepted during the times of war as it was identified for its various practical uses for wartime needs. During the 1980’s as the civilian aircraft sector expanded, investment casting became hugely popular and in demand. At present, coupled with the various computer technologies and modern techniques of casting, around 15% of the global industrial casting process is conducted with the help of investment casting methods.

Benefits of Investment Casting

- Investment casting boasts an excellent dimensional preciseness and tighter tolerances of 0.003 inches can be easily achieved.

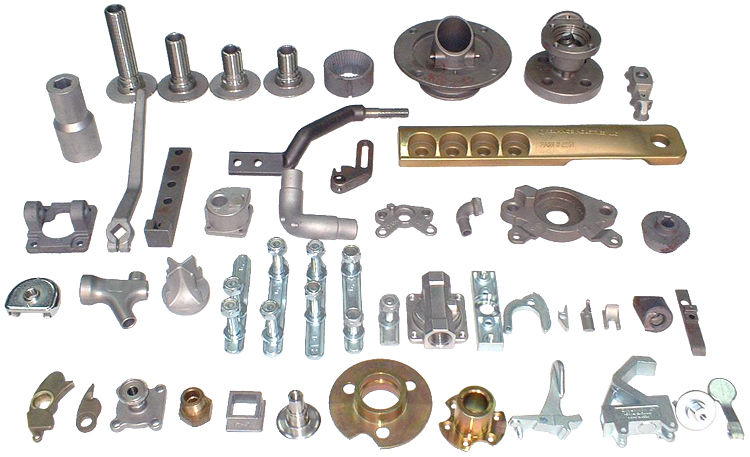

- With this form of casting, parts with extremely intricate shapes and distinctive features can be cast as a single portion.

- When compared to various other similar manufacturing processes, investment casting can attain excellent surface finish without any requirement of post-processing.

- Thin sections of about 0.015 inches can be cast without any occurrences of cold shut defects. This can be owed to the shorter length and shallow depth feature of investment casting.

- Herein, drafts on walls are not needed. However, if a master die is utilized to make wax patterns, then draft on the face are advised as it helps to make the pattern making the process much easier.

- Unlimited freedom is offered in terms of the use of investment cast materials. Most commonly, materials such as cast iron, non-ferrous alloys, and aluminum alloys are used herein. It is especially attractive for high-temperature alloys.

- The wax used in this process can be typically recovered for re-use.

- Stunning dimensional precision can be attained in combination with smooth cast surfaces. This capability of investment casting is immensely attractive for making products from a high temperature that are usually difficult to machine or which cannot be cast with metal mold techniques.

When it comes to determining the type of casting method you would choose for your production method, one should ponder over the various benefits of investment castings in India. However, in the end, it all comes down to the type of requirement you have in mind.